| Sign In | Join Free | My himfr.com |

|

- Home

-

Products

- Stainless Steel Strip(215)

- Stainless Steel Sheet(217)

- Stainless Steel Plate(337)

- Stainless Steel Pipe(358)

- Stainless Steel Bar(238)

- Galvanized Steel Coil(54)

- Steel Plate(106)

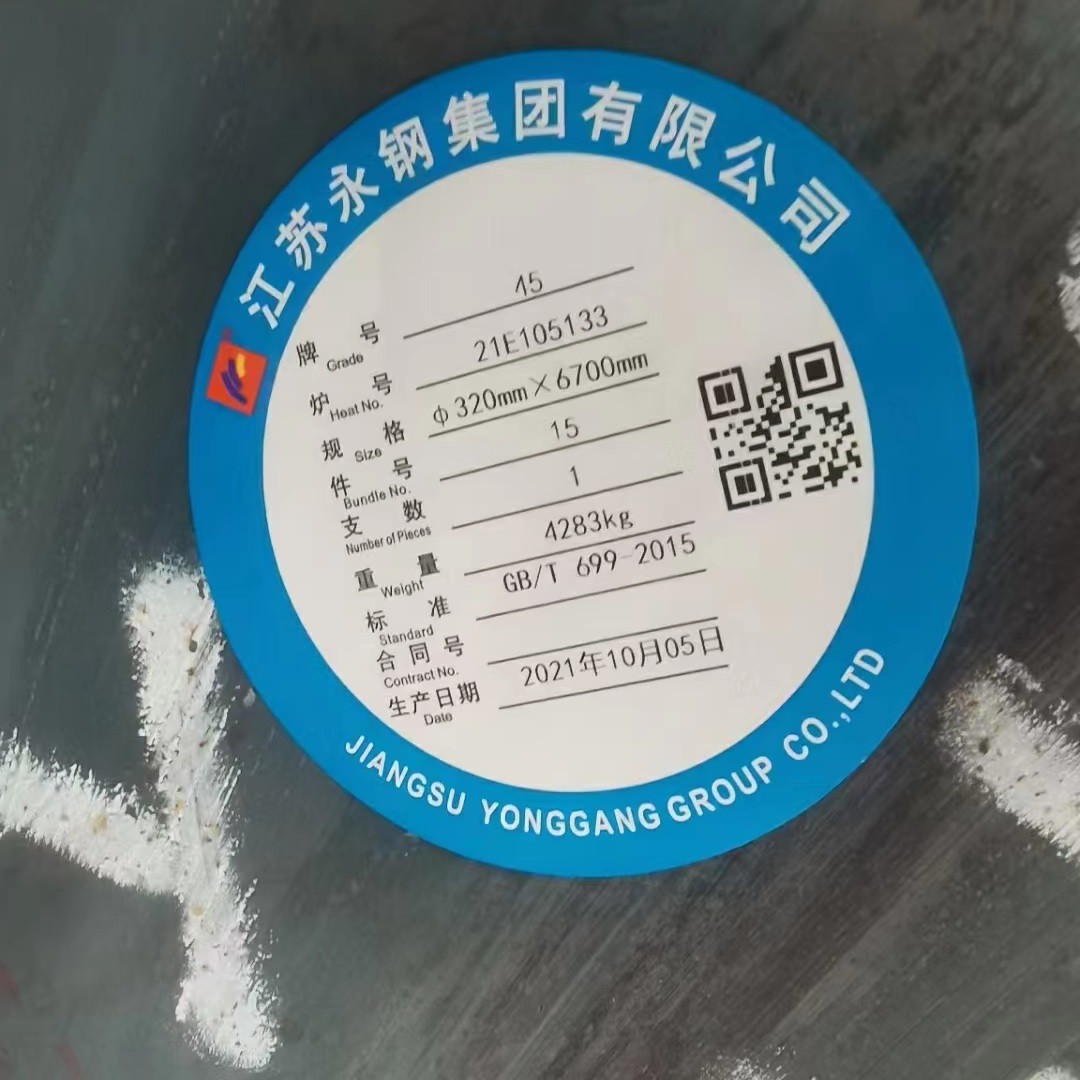

- Steel Round Bar(67)

- Nickel Alloy(230)

- Seamless Steel Pipe(61)

- Stainless Steel Beam(28)

- Copper Plate Sheet(25)

- Copper Round Bar(96)

- About Us

- Quality Control

- Contact Us

- Get Quotations