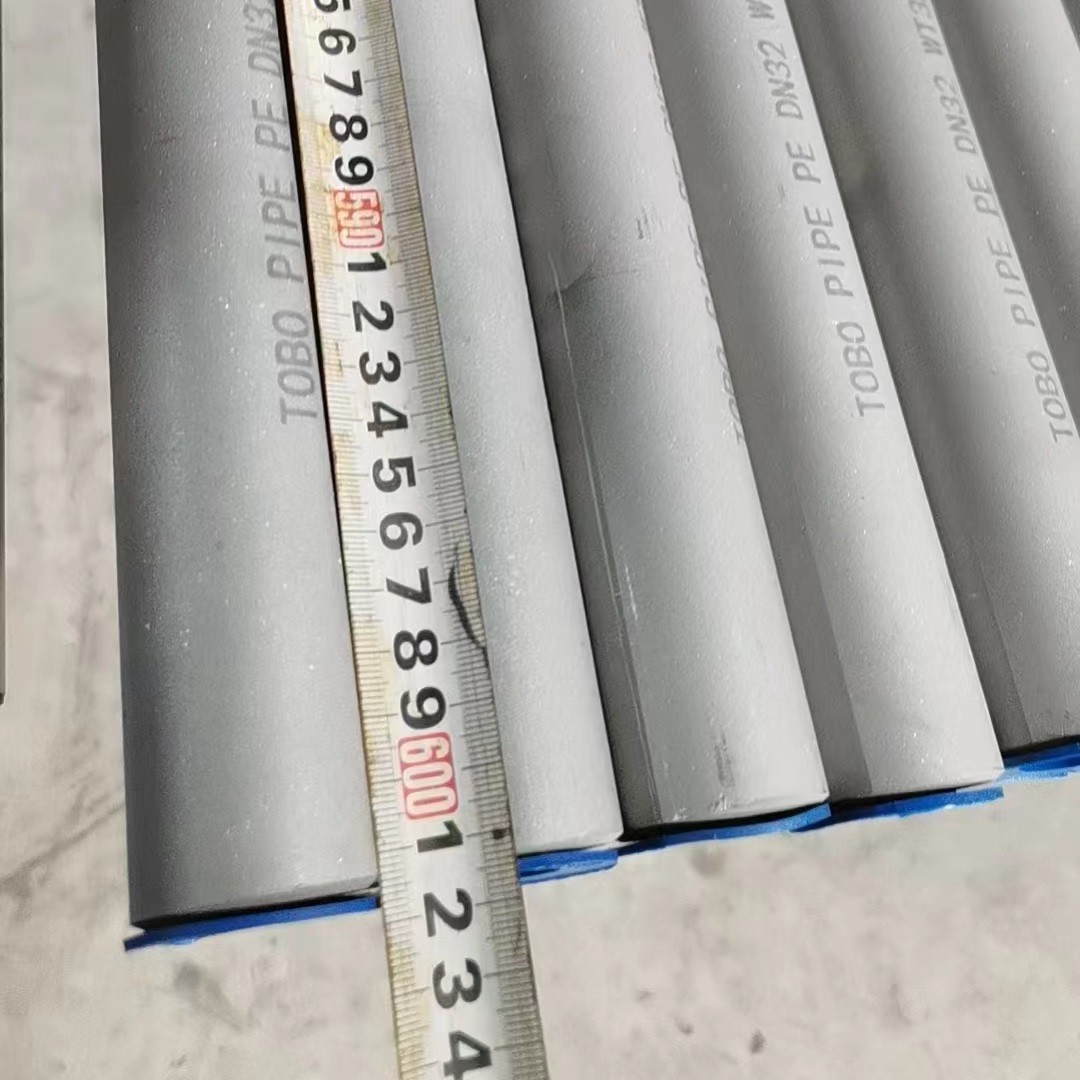

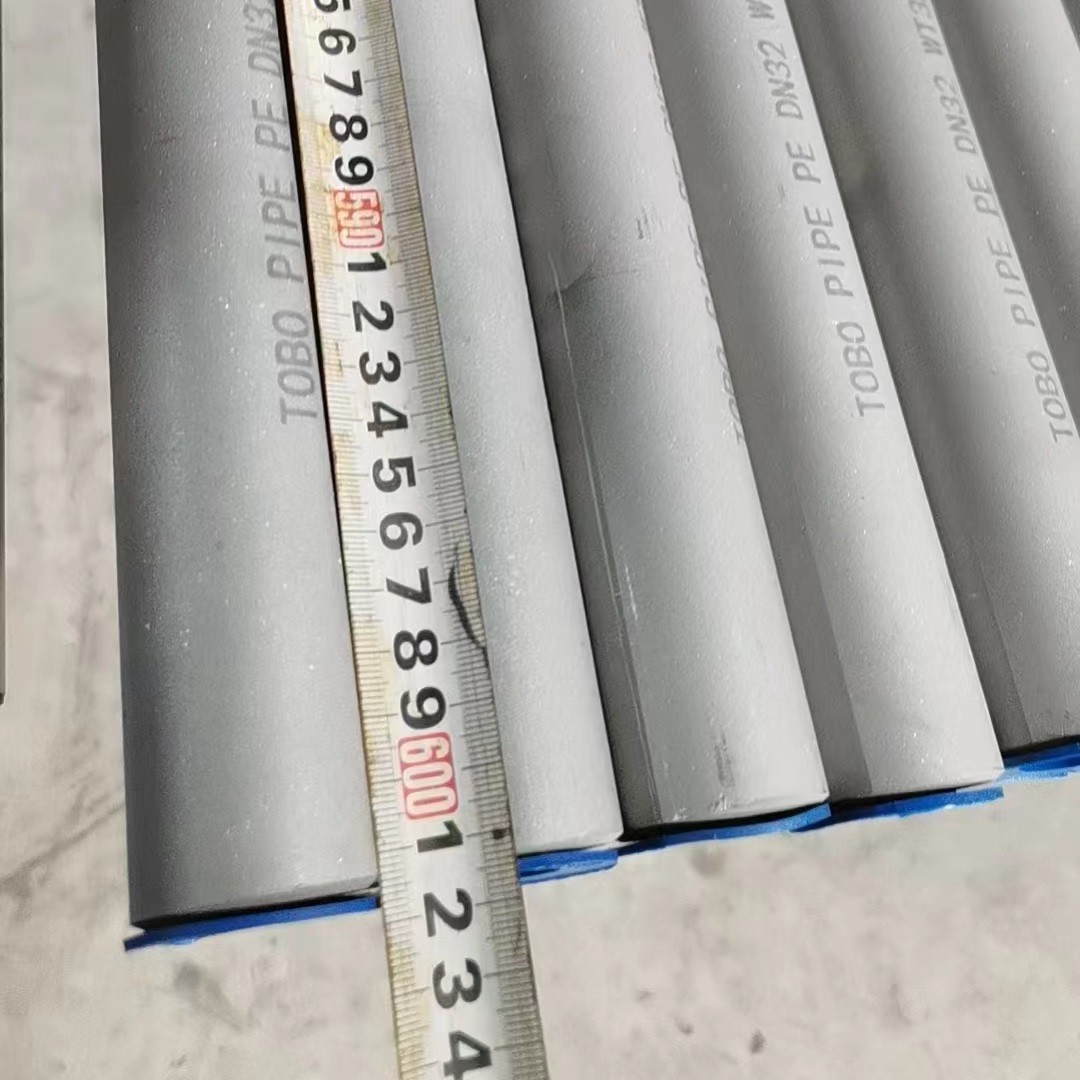

Seamless & Welded Stainless Steel Pipe Tube 316L / 1.4404 SCH40S SCH80S SCH160S

| TP316L Bright Annealed Tubing, 1/2inch Stainless Steel Tube |

| Outside Diameter | 3.2-25.4mm |

| Wall Thickness | 0.2-2.5mm |

| Length | As customer's requirement; In coil or in straight. |

| Standard | ASTM A213/ ASME SA213, ASTM A269/ASME SA269, EN10216-5, etc. |

| Grade | TP304, TP304L, TP316, TP316L, TP321, TP247H, etc. |

| Delivery Condition | Pickled, Polished, Bright Annealed |

| Technique | Seamless/Welded |

| Application | Automotive industry, Aircraft/Aerospace, Instrumentation & Electrical, Chemical Industry, etc. |

| Marking | LOGO, Standard, Grade, Size, Heat Number. |

| Package | Woven bag, wooden cases, or as per customer's requirement. |

| Quality Requirement | Mill Test Certificate (EN 10204/3.1); Third Part Inspection is acceptable. |

We have been manufacturing these 316L Stainless Steel Tubing and supplying them to customers in different countries. The raw material used in the production process of 316L Schedule 40 stainless steel pipe is procured from reliable vendors and are passed through various tests before fabricating them. Our well trained team of experts guides our customers in every step of decision making and enlightens them with the facts about the SS 316L Welded Pipe.

The Stainless Steel 316L Seamless Pipe produced by us has gained reputation in industrial as well as in commercial applications in the western world. Our timely and damage free delivery of Stainless Steel 316L Tube has made us well known in this industry.

Specifications of Stainless Steel 316L Seamless Pipe

| Specifications | ASTM A312 / ASME SA312 |

| O.D. | Sizes up to 12 inch NB, 6.00 mm Other Dia. upto 250 mm Other Dia. |

| SS 316L Pipe Thickness | 0.25, 0.28, 0.32, 0.37, 0.41, 0.51, 0.61, 0.71, 0.91, 1.11, 1.15, 1.41 mm |

| Grade | 316L |

| Type | Supplier in Welded | CDW | ERW | DOM | Seamless | Fabricated | CEW |

| Sizes | 5.0 milimeter - 1219.2 milimeter |

| Length | Single Random, Double Random, Cut to length |

| End | Screwed, Beveled, Threaded, Plain |

| Schedule Thickness Ranges | SCH XS, SCH 40, SCH 80S, SCH 5, SCH 80, SCH XXS, SCH 160, SCH10, All Schedules |

| Form | “U” Shape, Square, Pan Cake Coils, Coiled, Rectangular, Round, Hydraulic Tubes. |

| Surface Finish | 2B, No.1, No.4, No.8 Mirror Finish supplier in Mumbai |

| Delivery Condition | Annealed & Pickled, Polished, Bright & Annealed, etc |

Custom sizes of DIN 1.4404 AISI 316L Round Pipe in Single and Double Random Length, Visit us for SS 316L schedule 10 pipe thickness.

ASME SA 312 Grade 316L Square Pipe Wall Thickness

| 028 | = | .028" Thick |

| 035 | = | .035" Thick |

| 039 | = | .039" Thick |

| 049 | = | .049" Thick |

| 065 | = | .065" Thick |

| 083 | = | .083" Thick |

| 109 | = | .109" Thick |

Chemical Structure of 316L SS ERW Pipe

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

| 316L | .035 | 2.00 | .045 | .030 | 1.00 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

One of the Largest SS 316L pipe manufacturers in india, Know ASME SA 312 Gr.TP316L Square Pipe Weight Chart.

Weight Chart of 316L Stainless Steel Tubing

| NPS | O.D. | Wall Thk. | | Wght | Wght |

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| | | | 0.147 | 3.734 | 80 STD | 1.621 | 1.088 |

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| | | | 0.154 | 3.912 | 80 STD | 2.195 | 1.474 |

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| | | | 0.179 | 4.547 | 80 STD | 3.325 | 2.172 |

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| | | | 0.191 | 4.851 | 80 STD | 4.464 | 2.997 |

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| | | | 0.200 | 5.080 | 80 STD | 5.409 | 3.361 |

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| | | | 0.218 | 5.537 | 80 STD | 7.480 | 5.022 |

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| | | | 0.276 | 7.010 | 80 STD | 11.411 | 7.661 |

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| | | | 0.300 | 7.620 | 80 STD | 15.272 | 10.253 |

| 4″ | 4.500 | 114 | 0.237 | 6.020 | | 16.073 | 10.790 |

| | | | 0.337 | 8.560 | | 22.318 | 14.983 |

| 6″ | 6.625 | 168 | 0.188 | 4.775 | | 19.252 | 12.924 |

| | | | 0.203 | 5.516 | | 20.739 | 13.923 |

| | | | 0.219 | 5.563 | | 22.318 | 14.983 |

| | | | 0.250 | 6.350 | | 25.354 | 17.021 |

| | | | 0.280 | 7.112 | 40 STD | 58.263 | 18.974 |

| | | | 0.312 | 7.925 | | 31.334 | 21.036 |

| | | | 0.375 | 9.525 | | 37.285 | 25.031 |

| | | | 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 |

| | | | 0.500 | 12.700 | | 48.719 | 32.708 |

| 8″ | 8.625 | 219 | 0.188 | 4.775 | | 25.233 | 16.940 |

| | | | 0.203 | 5.156 | | 27.198 | 18.259 |

| | | | 0.219 | 5.563 | | 29.286 | 19.661 |

| | | | 0.250 | 6.350 | 20 | 33.308 | 22.361 |

| | | | 0.277 | 7.036 | 30 | 36.786 | 24.696 |

| | | | 0.322 | 8.179 | 40 | 42.352 | 28.554 |

| | | | 0.375 | 9.525 | | 49.216 | 33.041 |

| | | | 0.406 | 10.312 | 60 | 53.085 | 35.638 |

| | | | 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 |

| 10″ | 10.750 | 273 | 0.188 | 4.775 | | 31.588 | 21.207 |

| | | | 0.219 | 5.563 | | 36.689 | 24.631 |

| | | | 0.250 | 6.350 | 20 | 41.759 | 28.035 |

| | | | 0.307 | 7.798 | 30 | 51.002 | 34.240 |

| | | | 0.344 | 8.738 | | 56.946 | 38.231 |

| | | | 0.365 | 9.271 | 40 STD | 63.301 | 40.483 |

| | | | 0.438 | 11.125 | | 71.852 | 48.238 |

| | | | 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 |

| | | | 0.594 | 15.088 | 80 | 95.969 | 64.429 |

| 12″ | 12.750 | 324 | 0.188 | 4.775 | | 37.570 | 25.222 |

| | | | 0.219 | 5.563 | | 43.657 | 29.309 |

| | | | 0.250 | 6.350 | | 49.713 | 33.375 |

| | | | 0.281 | 7.137 | | 55.739 | 37.420 |

| | | | 0.312 | 7.925 | | 61.735 | 41.445 |

| | | | 0.375 | 9.525 | | 73.824 | 49.562 |

| | | | 0.406 | 10.312 | | 79.727 | 53.525 |

| | | | 0.500 | 12.700 | | 97.438 | 65.415 |

| | | | 0.562 | 14.275 | | 108.966 | 73.154 |

| 14″ | 14.000 | 356 | 0.188 | 4.775 | | 41.308 | 27.732 |

| | | | 0.219 | 5.563 | | 48.012 | 32.233 |

| | | | 0.250 | 6.350 | 20 | 54.685 | 36.713 |

| | | | 0.281 | 7.137 | | 61.327 | 41.172 |

| | | | 0.312 | 7.925 | | 67.939 | 45.611 |

| | | | 0.375 | 9.525 | STD | 81.281 | 54.568 |

| | | | 0.438 | 11.125 | 40 | 94.498 | 63.441 |

| | | | 0.500 | 12.700 | XHY | 107.381 | 72.090 |

| | | | 0.625 | 15.875 | | 132.983 | 89.278 |

| 16” | 16.000 | 406 | 0.188 | 4.775 | | 47.290 | 21.748 |

| | | | 0.219 | 5.563 | | 54.980 | 36.910 |

| | | | 0.250 | 6.350 | 10 | 62.639 | 42.053 |

| | | | 0.281 | 7.137 | | 70.268 | 47.174 |

| | | | 0.312 | 7.925 | 20 | 77.866 | 52.275 |

| | | | 0.344 | 8.738 | | 85.677 | 57.519 |

| | | | 0.375 | 9.525 | 30 STD | 93.213 | 62.578 |

| | | | 0.438 | 11.125 | | 108.433 | 72.797 |

| | | | 0.500 | 12.700 | 40 XHY | 123.289 | 82.770 |

| 18″ | 18.000 | 457 | 0.219 | 5.563 | | 61.948 | 41.588 |

| | | | 0.250 | 6.350 | | 70.593 | 47.393 |

| | | | 0.281 | 7.137 | | 79.208 | 53.176 |

| | | | 0.312 | 7.925 | 20 | 87.792 | 58.939 |

| | | | 0.375 | 9.525 | STD | 105.144 | 70.588 |

| | | | 0.438 | 11.125 | 30 | 122.369 | 82.152 |

| | | | 0.500 | 12.700 | XHY | 139.198 | 93.450 |

| | | | 0.562 | 14.275 | 40 | 155.904 | 104.666 |

| | | | 0.625 | 15.875 | | 172.754 | 115.978 |

| 20″ | 20.000 | 508 | 0.250 | 6.350 | | 78.547 | 52.733 |

| | | | 0.282 | 7.163 | | 88.458 | 59.386 |

| | | | 0.312 | 7.925 | | 97.719 | 65.604 |

| | | | 0.375 | 9.525 | 20 STD | 117.075 | 78.598 |

| | | | 0.438 | 11.125 | | 136.305 | 91.508 |

| | | | 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 |

| | | | 0.594 | 15.088 | 40 | 183.378 | 123.110 |

| | | | 0.625 | 15.875 | | 192.640 | 129.328 |

| | | | 0.688 | 17.475 | | 211.368 | 141.901 |

| 24″ | 24.000 | 610 | 0.250 | 6.350 | | 94.456 | 63.413 |

| | | | 0.281 | 7.137 | | 106.029 | 71.183 |

| | | | 0.312 | 7.925 | | 117.573 | 18.932 |

| | | | 0.375 | 9.525 | 20 STD | 140.938 | 64.618 |

| | | | 0.438 | 11.125 | | 164.176 | 110.219 |

| | | | 0.500 | 12.700 | XHY | 186.923 | 125.490 |

| | | | 0.625 | 15.875 | | 232.410 | 156.028 |

| | | | 0.688 | 17.475 | 40 | 255.148 | 171.293 |

| | | | 0.750 | 19.050 | | 277.401 | 186.233 |

| 30″ | 30.000 | 762 | 0.250 | 6.350 | | 118.318 | 79.433 |

| | | | 0.281 | 7.137 | | 132.851 | 89.189 |

| | | | 0.312 | 7.925 | 10 | 147.353 | 98.925 |

| | | | 0.375 | 9.525 | STD | 176.731 | 118.648 |

| | | | 0.438 | 11.125 | | 205.983 | 138.286 |

| | | | 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 |

| | | | 0.625 | 15.875 | 30 | 292.066 | 196.078 |

| | | | 0.688 | 17.475 | | 320.817 | 215.380 |

| | | | 0.750 | 19.050 | | 348.988 | 234.293 |

| 36″ | 36.000 | 914 | 0.250 | 6.350 | | 142.180 | 95.453 |

| | | | 0.281 | 7.137 | | 159.672 | 107.196 |

| | | | 0.312 | 7.925 | 10 | 177.133 | 118.918 |

| | | | 0.375 | 9.525 | STD | 215.525 | 142.678 |

| | | | 0.438 | 11.125 | | 247.790 | 166.353 |

| | | | 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 |

| | | | 0.625 | 15.875 | | 351.723 | 236.128 |

| | | | 0.688 | 17.475 | | 386.487 | 259.467 |

| | | | 0.750 | 19.050 | | 420.576 | 282.353 |

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | | 206.914 | 138.911 |

| | | | 0.375 | 9.525 | STD | 248.319 | 166.708 |

| | | | 0.500 | 12.700 | XHY | 33.097 | 221.610 |

| | | | 0.750 | 19.050 | | 492.163 | 330.413 |

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| | | | 0.438 | 11.125 | | 331.404 | 222.487 |

| | | | 0.500 | 12.700 | XHY | 377.822 | 253.650 |

| | | | 0.750 | 19.050 | | 563.750 | 378.473 |

| | | | 0.875 | 22.225 | | 655.969 | 440.383 |

UNS S31603 Rectangular Pipe Mechanical Properties Tensile Strength

| Grade | Tensile |

| | Ultimate/Min | Yield/Min | Elongation/Min |

| | KSI | MPA | KSI | MPA | % |

| 316L | 70 | 485 | 25 | 170 | 35 |

Equivalent material of Stainless Steel 316L Pipe

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 316L | 1.4404 / 1.4435 | S31603 | SUS 316L | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | Z3CND17‐11‐02 / Z3CND18‐14‐03 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Various Types of Test on SS 316L Tubing

- Radiography/ Hydrostatic test

- Micro/ Macro test

- Hardness test

- Chemical/ Mechanical test

- IGC/ PMI test

- Pitting resistance test

ASTM A312 Gr TP316L Welded Pipe Roughness

| MATERIAL SURFACE | ABSOLUTE ROUGHNESS COEFFICIENT

Ε MM |

| Aluminum Alloy, Lead | 0.001 - 0.002 |

| Drawn Copper/ Brass | 0.0015 |

| SS 316L | 0.015 |

Physical Analysis of 316L Stainless Steel Square Tube

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion (m/m/0C) | Thermal Conductivity (W/m.K) | Specific Heat 0-1000C (J/kg.K) | Electrical Resistivity (n.m) |

| 0-1000C | 0-3150C | 0-5380C | at 1000C | at 5000C |

| 316L | 8000 | 193 | 15.9 | 16.2 | 17.5 | 16.3 | 21.5 | 500 | 740 |

Stainless Steel Marine 316L SEamless Tubing Surface Finish

| Surface Finish | Internal Surface(ID) | External Surface(OD) |

| Roughness Average(RA) | Roughness Average(RA) |

| μ inch | μm | μ inch | μm |

| AP | Annealed & Pickled | Not defined | Not defined | 40 or Not defined | 1.0 or Not defined |

| BA | Beight Annealed | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| MP | Mechanical Polish | 40,32,25,20 | 1.0,0.8,0.6,0.5 | 32 | 0.8 |

| EP | Electro Polish | 15,10,7,5 | 0.38,0.25,0.20;0.13 | 32 | 0.8 |

JIANGSU MITTEL STEEL INDUSTRIAL LIMITED

Our company is located in Wuxi City, China, we are a stainless

steel plate, seamless steel pipe, round steel, steel belt,

decorative pipe and other products distribution wholesale private

enterprise. Our company operates stainless steel plate, seamless

steel pipe, round steel, steel belt, decorative pipe best-selling

consumer market. Without our products among consumers enjoy a

higher status, the company with a number of retailers and agents to

establish a long-term stable cooperative relationship. Our

distribution of stainless steel plate, seamless steel pipe, round

steel, steel belt, decorative pipe variety complete, reasonable

price. The strength of the company, heavy credit, abide by the

contract, ensure product quality, with a variety of management

characteristics and the principle of small profits, to win the

trust of our customers.