JIANGSU MITTEL STEEL INDUSTRIAL LIMITED

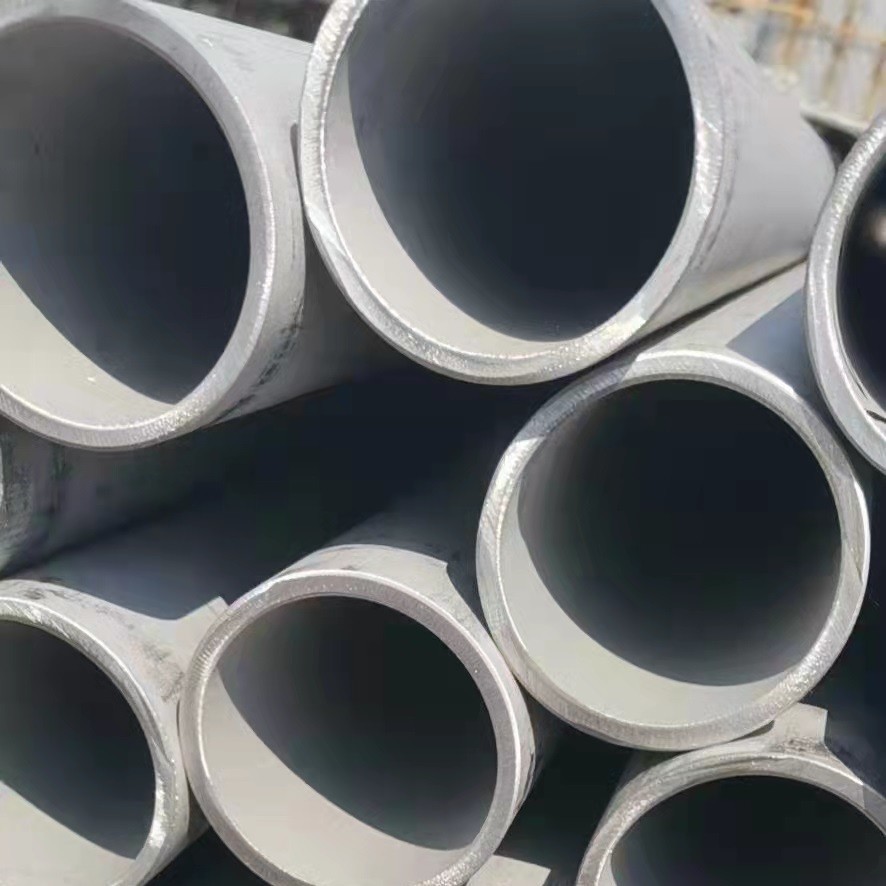

Our company is located in Wuxi City, China, we are a stainless

steel plate, seamless steel pipe, round steel, steel belt,

decorative pipe and other products distribution wholesale private

enterprise. Our company operates stainless steel plate, seamless

steel pipe, round steel, steel belt, decorative pipe best-selling

consumer market. Without our products among consumers enjoy a

higher status, the company with a number of retailers and agents to

establish a long-term stable cooperative relationship. Our

distribution of stainless steel plate, seamless steel pipe, round

steel, steel belt, decorative pipe variety complete, reasonable

price. The strength of the company, heavy credit, abide by the

contract, ensure product quality, with a variety of management

characteristics and the principle of small profits, to win the

trust of our customers.