The common forms of 52100 steel material include sheets, plates,

hot-rolled bars, annealed bars, and cold-drawn bars. These are

further discussed below:

Sheet

Sheets are flat pieces of 52100 steel material that come in various

thicknesses. They are commonly used if a flat, sturdy surface is

required, such as in: machine components, tooling, and industrial

equipment.

Bar

Bars are cylindrical solid forms of 52100 steel material that come

in different diameters. They are often utilized for applications

that require high strength, hardness, and wear resistance, such as:

bearings, shafts, gears, and other mechanical components.

Plate

Plates are thicker versions of sheets, and they are commonly used

in applications that demand more strength and durability, such as:

heavy machinery, structural components, and tooling.

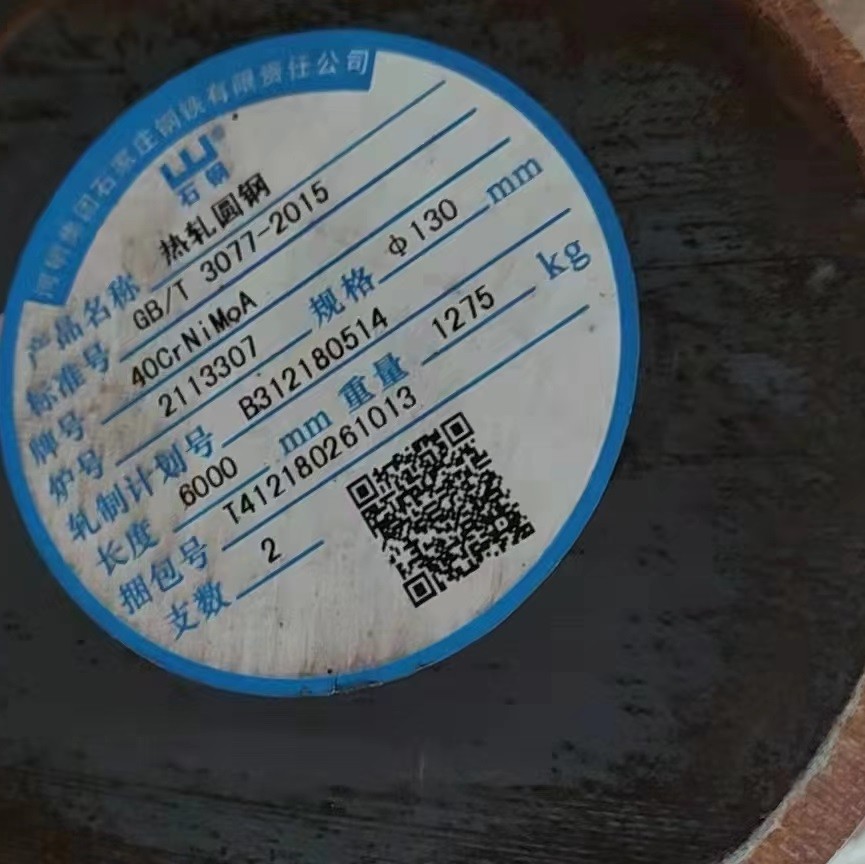

Hot Rolled

Hot-rolled bars are formed by heating the 52100 steel material to a

high temperature and then rolling it into the desired shape. This

process improves the mechanical properties of the steel, making it

stronger and tougher.

Annealed

Annealed bars are heat-treated to relieve internal stresses and

improve machinability. This process involves heating the steel to a

specific temperature and then gradually cooling it, resulting in a

softer and more workable material.

Cold Drawn

Cold-drawn bars are produced by pulling the 52100 steel material

through a die to form it into the proper shape and size. This

process enhances the surface finish, dimensional accuracy, and

mechanical properties of the bars, making them suitable whenever

precise dimensions and excellent surface quality are paramount.

What Are Equivalents of 52100 Steel?

The equivalents for 52100 steel are provided in the table below: