| ASTM / ASME Grade | ASTM A312 / ASTM SA 312 |

| Dimensional ANSI Specifications | ANSI/ ASME B36.19M, ANSI/ ASME B36.10M |

| Different Types and Forms | Rectangle, Hex, Honed, Square, Round, Hydraulic Pipe supplier |

| Basic types we produce | 100% X Ray Welded, CDW, ERW, Welded, Seamless, Fabricated |

| Pipe End Bevel | Plain, Beveled and Treaded End |

| Delivery & Finished Condition | Bright Annealed, Cold Drawn, Polished, Annealed and Pickled, Pickled and Passivated |

| Mechanical Surface Finish | 2B, No.4, No.1, No.8 Mirror Finish or custom Finish as per customer Requirements |

| ASTM A312 TP316L Wall Thickness | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Other Facilities we offer | Grooving, Threading, Machining, Ultrasonic Testing, Customer Tagging/ Marking, Destructive, MTR’s Available, Threading, Polishing, Export Documentation, Non Destructive, Beveling, Export Packaging, Cutting, Color Coding, Material testing |

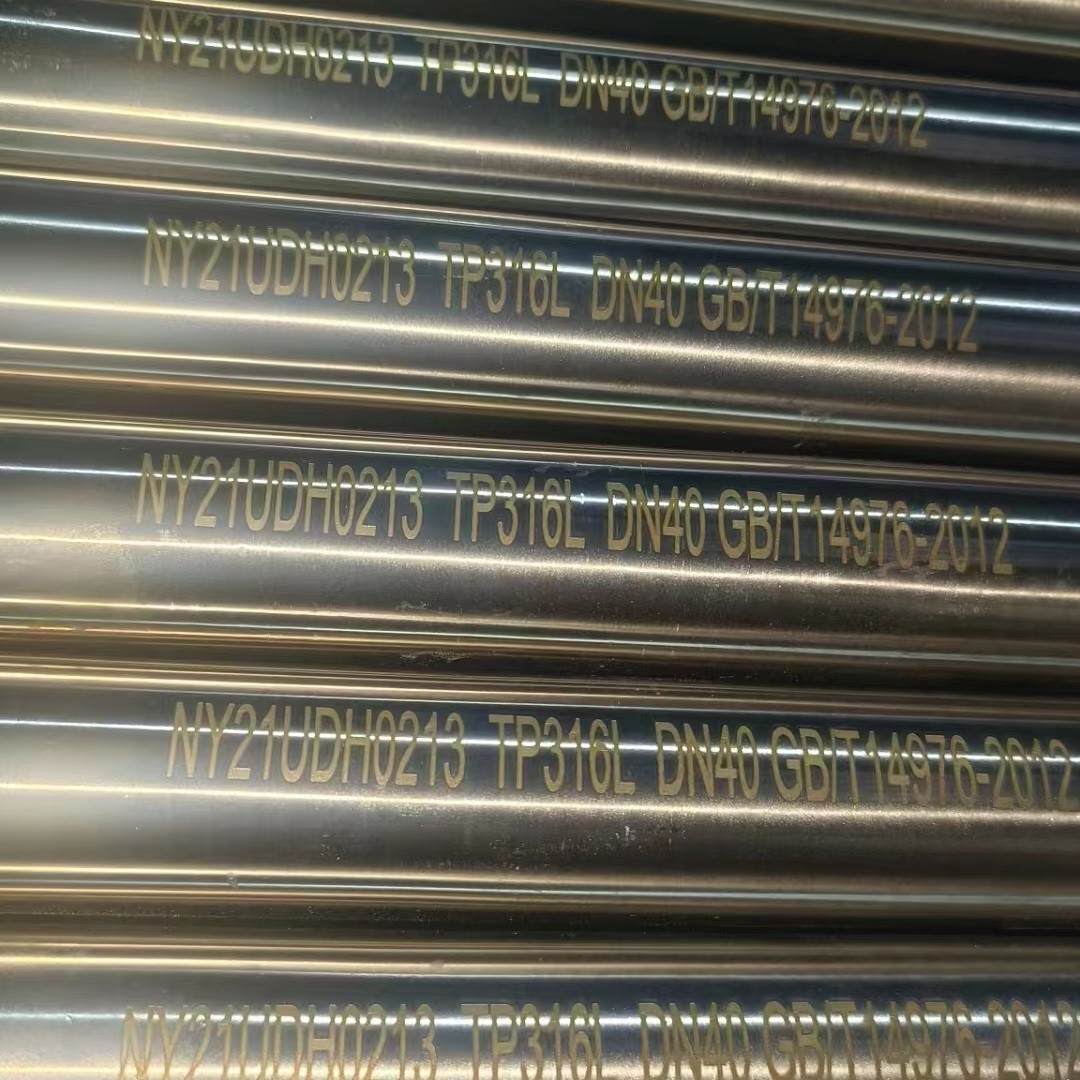

| SS 316L Pipes Marking | - Specification

- Grade

- Nominal Pipe Sizes

- Pipe Schedule or Wall Thickness

- Manufacturing Method (Seamless / Welded)

- Heat Number

- Manufacturer/ Supplier Name or Custom Logo - on request

Marked Pipe Sample: ANSI B36.19 ASTM A312 TP316L 12" NB SCH 60S SEAMLESS HEAT NO. XXXX |

| Dual certified 316L Pipe supplier | Dual certification : To certify ASTM A312 316L and ASME SA312 316L material specification |