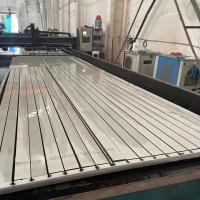

Product Name | 310 / 310H Stainless Steel Sheets |

Material Type | Ferrite stainless steel, magnetic; Austenitic stainless steel,

Non-magnetic. |

| 300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 |

200series:201,202,202cu,204 |

400series:409,409L,410,420,430,431,439,440,441,444 |

Others:2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039

904L,etc |

Duplex stainless steel:S22053,S25073,S22253,S31803,S32205,S32304 |

Special Stainless Steel:904L,347/347H,317/317L,316Ti,254Mo |

Technology | Cold Rolled /Hot Rolled |

Length | 2000/2438/2500/3000/3048 mm |

Width | 1000/1219/1250/1500 mm |

Thickness | 0.4-3mm(cold Rolled), 3-200mm(hot Rolled) |

Surface | BA, 2B, NO.1,2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed,perforated etc. |

Leveling: improve flatness, esp. for items with high flatness

request. |

Skin-Pass: improve flatness, higher brightness |

Other Choices | Cutting:Laser cutting, help the customer to cut the required size |

Protection | 1. Inter paper available |

2. PVC protecting film available |

Price Item | FOB,CIF,DDU,FCA,EXW ,.etc |

|

Quality Assurance | 1.Provide MTC (Mill Test).2.Accept the inspection by the third party agent |