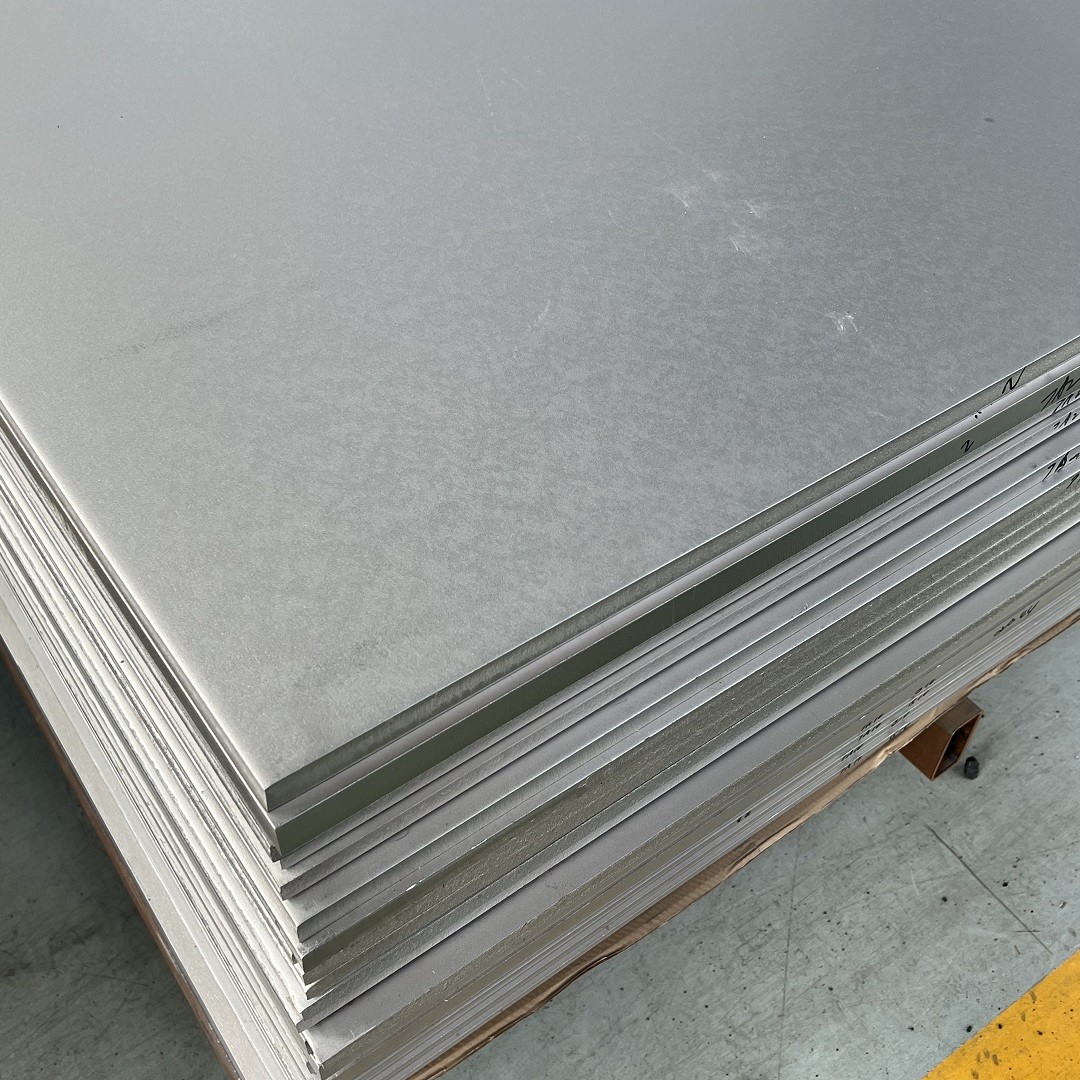

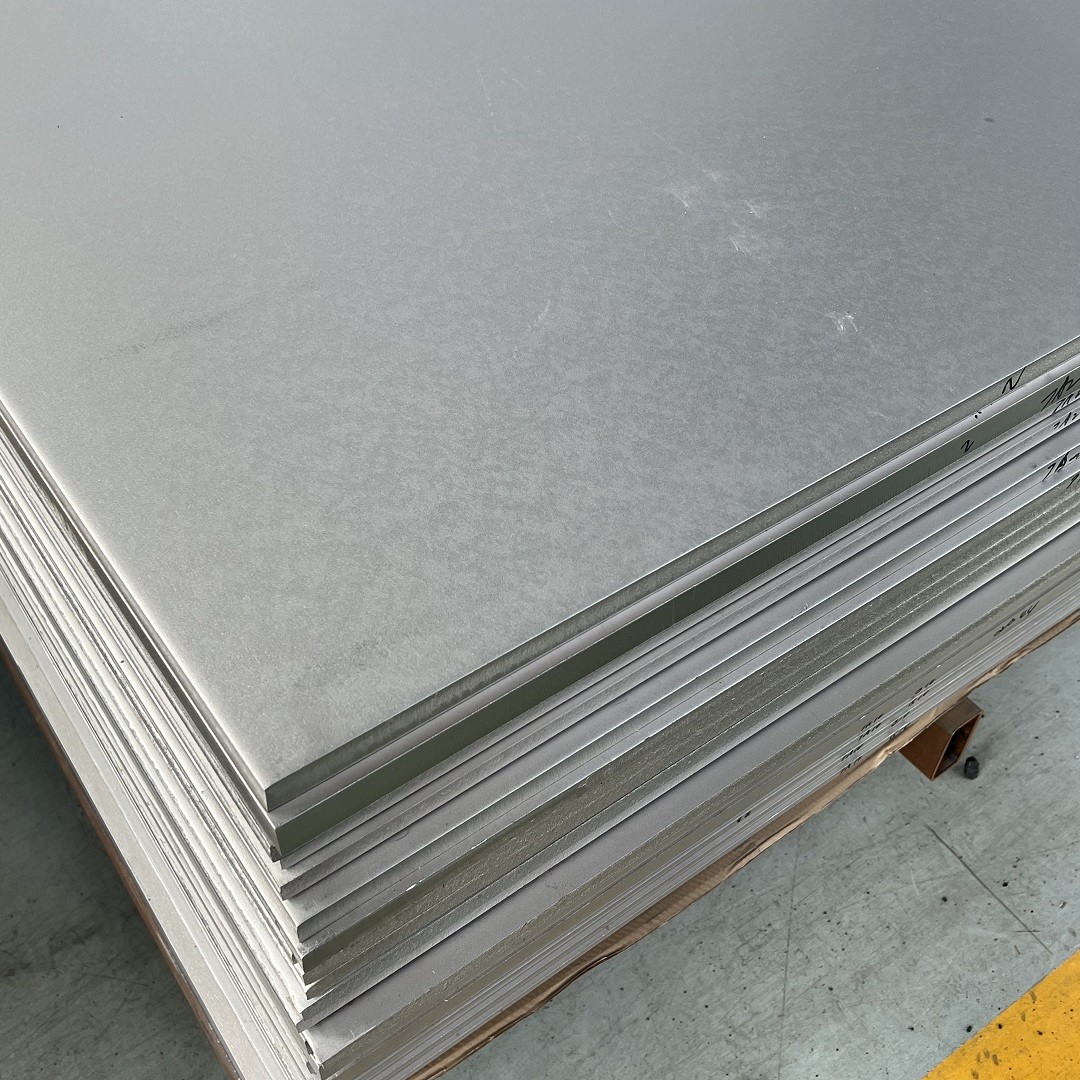

Titanium Plate GR2 Titanium Grade 2 / UNS R50400 Plate 1500*6000mm

Hot Rolled

| Grade | TA1, TA2, TA3, TA4, TA10, TA15, TA17, GR1, GR2, GR3, GR4, GR5, GR7,

GR9,

GR11, GR12 |

| Size | T(3.0mm~120mm)*W(800mm~2200mm)*L

T(0.4mm~3mm)*W(1500mm max)*L |

| Standard | ASTM B 265, ASME SB265 AMS491 |

| Application | Chemical, industry, sports etc. |

| Feature | High corrosion resistance, low density, good thermal stability |

| Surface | Bright, Polished, Pickling, Acid cleaning, Sandblasting |

| Quality and test | Hardness test, Bending test, Hydrostatic etc. |

| Finish | Roll-up(Hard) |

| Surface | Polished |

Titanium Grades 1, 2, 3 and 4 are commercially pure (99% minimum

titanium). Each grade has slight variations in chemical composition

that affect mechanical properties and design capability. The

corrosion resistance is similar across all four grades. Titanium is

light weight, exceptionally corrosion resistant and often exceeds

the corrosion resistance of stainless steels in most environments.

Of the four commercially pure (C.P.) titanium grades, Grade 2 is

the alloy of choice for most industrial applications that require

good ductility and corrosion resistance.

Chemical Composition (%)1 – Grade 2

| (Ti) Titanium | Remainder |

| (Fe) Iron | 0.30 max |

| (O) Oxygen | 0.25 max |

| (C) Carbon | 0.08 max |

| (N) Nitrogen | 0.03 max |

| (H) Hydrogen2,3 | 0.015 max |

Applicable Specifications*

| Form | ASTM | ASME | Military Standard | AMS |

| Bar | B348 | SB348 | MIL-T-9047 | 4902 |

| Plate & Sheet | B265 | SB265 | MIL-T-9046 CP-3 | 4902 |

Industries & Applications

Titanium Grade 2 has a lower density making it very desirable where

weight can be a concern. Medical and aerospace are two key

industries for titanium alloys. The strength and corrosion

resistance properties of titanium Grade 2 also make it well suited

to applications in the marine, chemical processing and desalination

industries. Typical applications for Grade 2 titanium include oil &

gas components, reaction and pressure vessels, tubing or piping

systems, heat exchangers, liners, flue-gas desulphurization systems

and many other industrial components. Continuous service

temperatures can reach up to 800°F with occasional, intermittent

service at 1000°F.

Resistance to Corrosion

Titanium’s C.P. grades corrosion resistance comes from a strongly

adherent, stable, protective oxide film, which forms in the presence

of oxygen. This film makes the commercially pure titanium grades

resistant to most oxidizing, neutral and inhibited reducing, as

well as mildly reducing environments. Grade 2 offers excellent

resistance to seawater and marine atmospheric corrosion. Corrosion

resistance is similar between the four C.P. grades, but mechanical

properties vary along with varying oxygen and iron contents. Grade

2 titanium is resistant to attack from moist chlorides and metallic

chlorides, chlorite and hypochlorite solutions, nitric and chromic

acids, organic acids as well as many gaseous industrial

applications.

Fabrication and Heat Treatment

Titanium Grade 2 has good ductility, which allows for cold

formability. To prevent cold forming concerns, the minimum bend

radius for material under 0.070″ thick should be 2T, while 2.5T

should be used for material over 0.070″. The material can also be

easily machined, hot worked and welded. Hot working should be

performed between 400°F and 600°F. Stress relieving should be

performed by heating to a temperature between 900°F and 1100°F

followed by either forced air or slow cooling. Annealing

temperatures range from 1200°F to 1400°F for 6 minutes to 2 hours

followed by an air cool.

Welding of Grade 2 titanium can be performed using various methods

such as MIG and TIG. Inert gas shielding is crucial to prevent

oxygen pickup and embrittlement of the weld area. A mixture of

argon and helium is typically preferred but should be tested prior

to accepting a welding procedure. Preheat or post heat treatments

are not required.