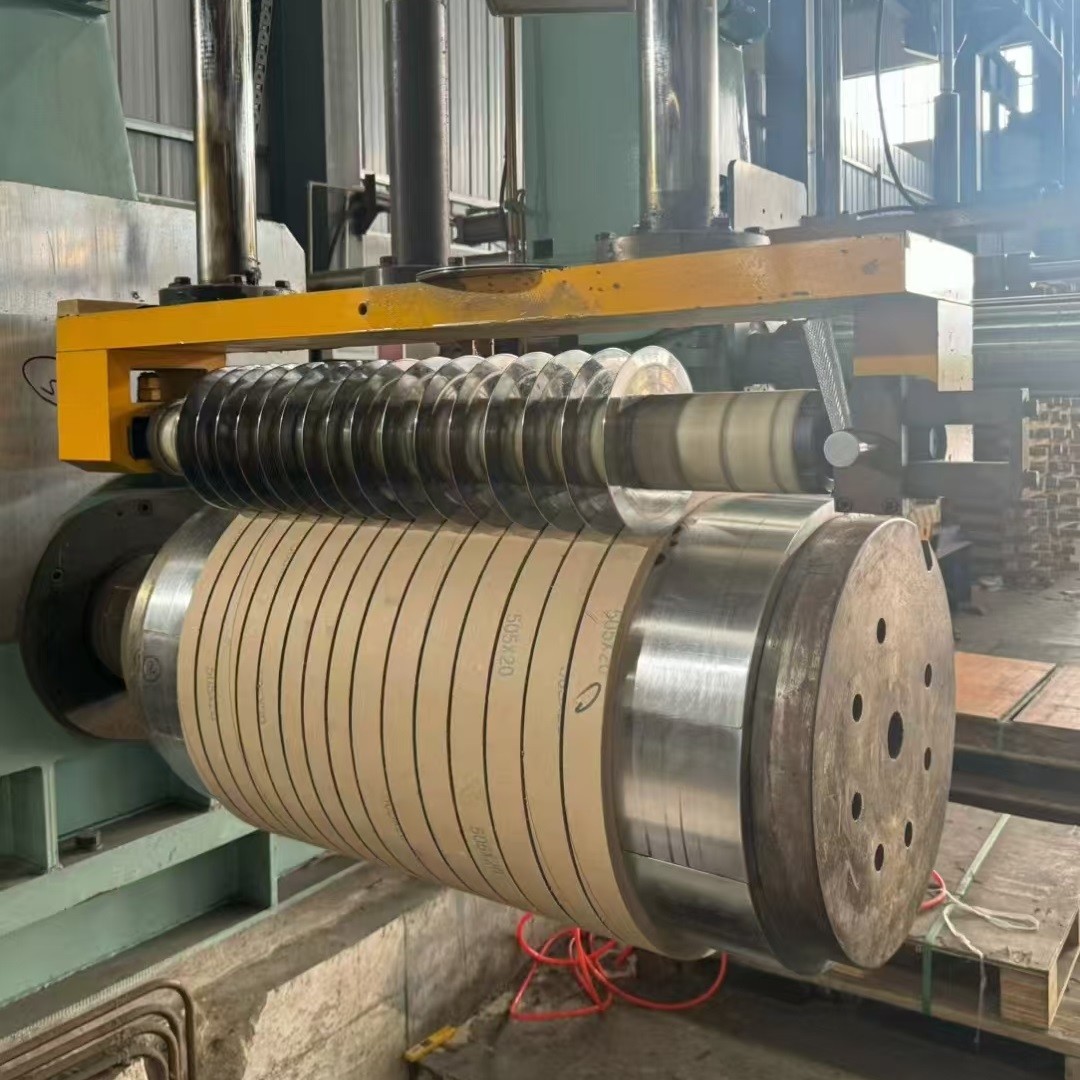

301 Stainless Steel Strips 0.1 - 2.0mm Cold Rolled Precison SS

Strip Coils Width 10 - 1219mm

| Product Name | Stainless Steel Strips |

| Length | As required |

| Width | 3mm-1219mm or as required |

| Thickness | 0.15 - 3.0mm or as required |

| Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

| Technique | Hot rolled / cold rolled |

| Surface Treatment | 2B or according to customer requirement |

| Thickness tolerance | ±0.01mm |

| Material | 201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L,

321,310S 309S, 410, 410S,420, 430, 431, 440A,904L |

| Application | It is widely used in high temperature applications, medical

devices, building materials, chemistry, food industry, agriculture,

ship components.It also applies to food, beverage packaging,

kitchen supplies, trains, aircraft, conveyor belts, vehicles,

bolts, nuts, springs, and screen. |

|

| MOQ | 1tons.We also can accept sample order. |

| Shipment time | Within 15-20 workdays after receiving deposit or L/C |

| Export packing | Waterproof paper, and steel strip packed.Standard Export Seaworthy

Package.Suit for all kinds of transport,or as required |

|

| Capacity | 250,000 tons/year |

301 stainless steel strips are a high strength, high hardness

stainless steel product, belongs to the austenitic stainless steel,

its chemical composition contains 17% chromium and 7% nickel. 301

stainless steel strips have good corrosion resistance, high

strength and hardness, good processing properties, and

high-temperature resistance, so it is widely used in electronics,

machinery, chemicals, construction, automotive, aerospace, and

other fields.

301 stainless steel strips can be processed and formed by a variety

of processing methods, such as cold processing, hot processing,

cold drawing, cold rolling, etc., and can be made into a variety of

shapes and sizes, such as springs, shrapnel, syringes, films, etc.

301 stainless steel strips also have good plasticity and

machinability, easier to bend and deformation in the process, can

be used to make complex shapes and structures.

Compared with other stainless steel products, 301 stainless steel

strips have higher hardness and strength, as well as good corrosion

resistance and high-temperature resistance, and can be used in

harsh working environments, so it is widely used in areas requiring

high strength and high hardness.

Product Range of 301 Stainless Steel Strips

| Contents | Precision Stainless Steel Strip | Cold-Rolled Stainless Steel Strip |

| Range Specification | 0.02≤Hardness≤0.5mm | Hardness≥0.3mm |

| Thickness Tolerance | Thickness≤0.1mm ±2.5μm Thickness≤0.5mm ±5μm | Thickness≤0.6mm ±40μm Thickness≤1.0mm ±50μm |

| Uniformity of Hardness | ±10HV | No requests |

| Width Tolerance | Width≤30mm ±0.015mm Width≤100mm ±0.03 mm Width≤250mm ±0.05 mm Width≤610mm ±0.1 mm | Width≤1524mm +5mm |

| Straightness | 1-2 IU | Min 3 IU |

| The Burr Height and Edge Quality | Thickness 0.02-0.1mm ≤6% Thickness 0.1-0.5mm ≤5% There are special requirements for deburring or round-edged strip

steel | Thickness 0.4mm Burr height 0.03mm Thickness 3.0mm Burr height 0.09mm No requests |

Chemical Composition of 301 Stainless Steel Strips

| 301 | C % | Si % | Mn % | P % | S % | Ni % | Cr % | Mo % | N % |

| ASTM | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

| DIN/EN | 0,07 | 1,00 | 2,00 | 0,045 | 0,030 | 6,0-8,0 | 16,0-18,0 | – | 0,1 |

| JIS | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | – |

| GB | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 6.0-8.0 | 16.0-18.0 | – | 0.1 |

Physical Property of 301 Stainless Steel Strips

| 301 | Density (g/cm³) | Melting point (℃) | Thermal conductivity (W/m-K) | Coefficient of thermal expansion (10^-6/K) |

| ASTM | 7.93 | 1400-1450 | 16.3 | 17.2 |

| JIS | 7.93 | 1399-1454 | 16.3 | 17.2 |

| EN | 7.9 | 1400-1450 | 16.2 | 17.2 |

| GB | 7.93 | 1398-1454 | 16.3 | 17.2 |

Mechanical Property of 301 Stainless Steel Strips